A Century of Innovation:

The Champion Friction Technologies Story

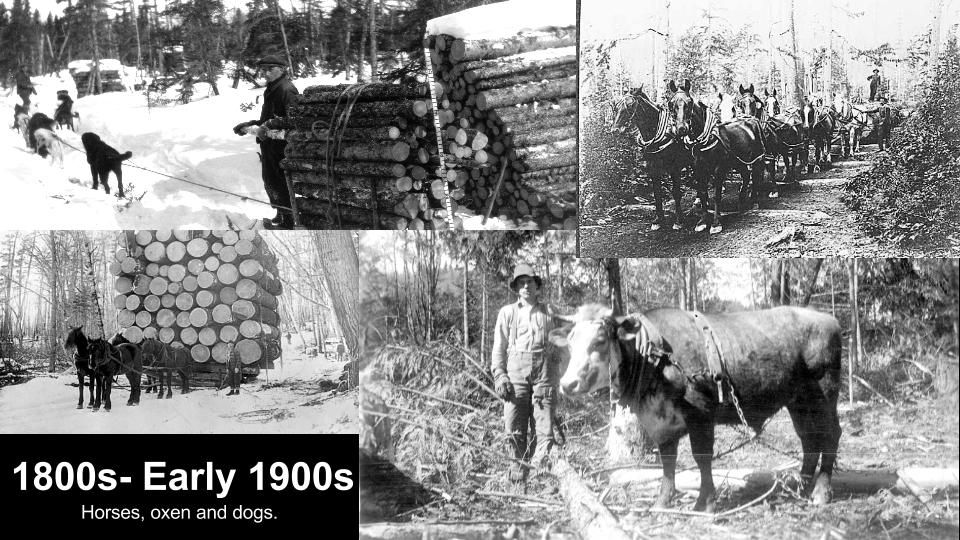

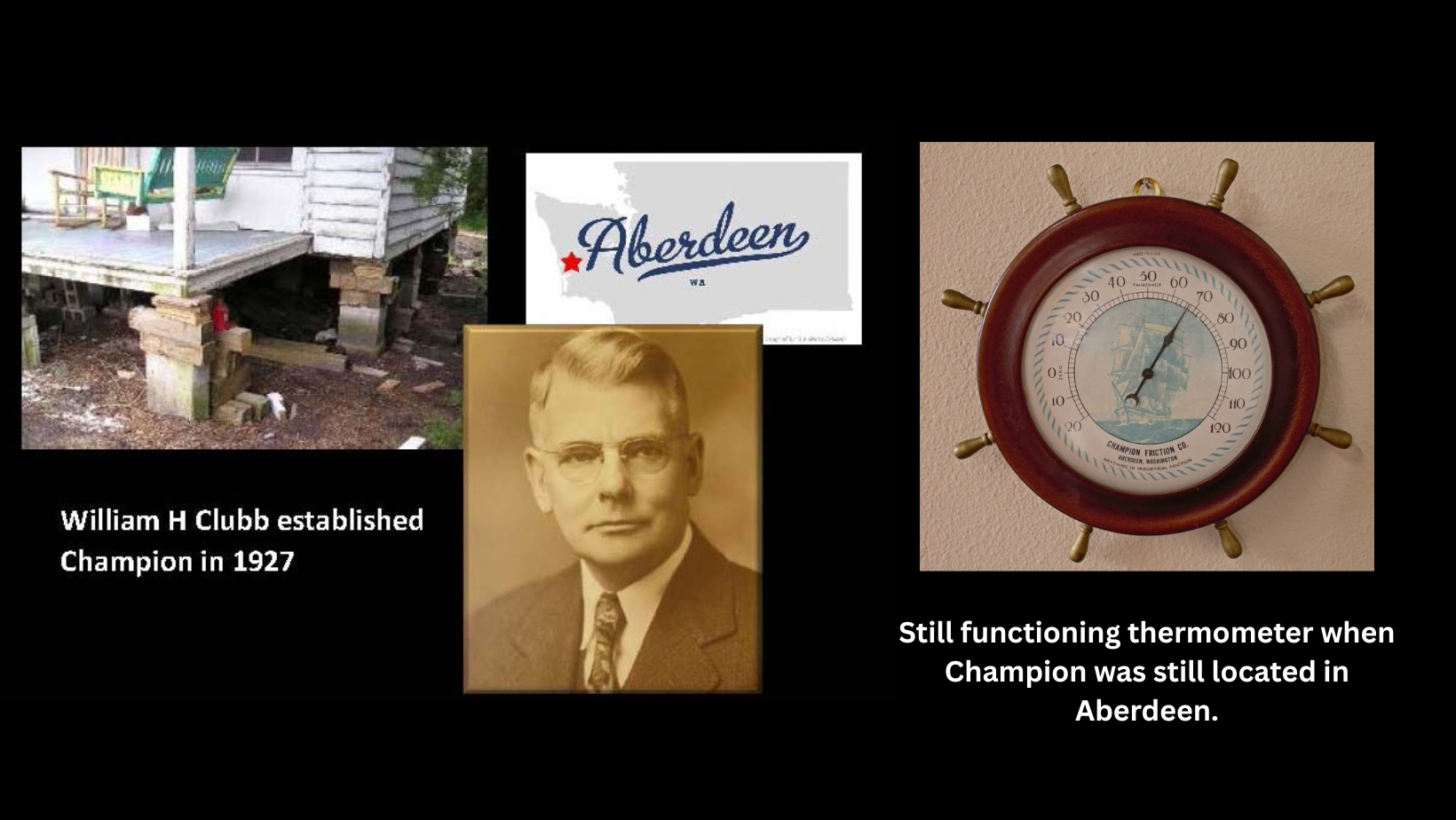

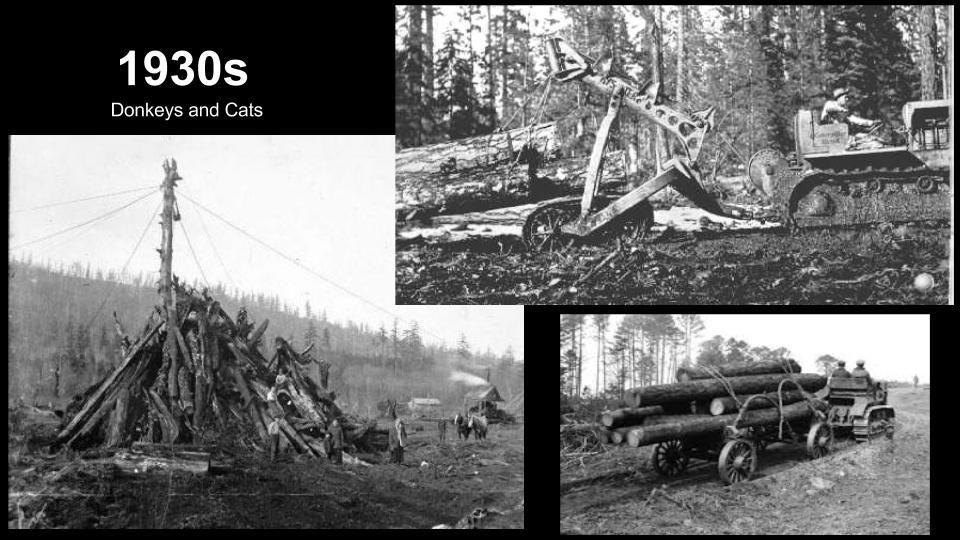

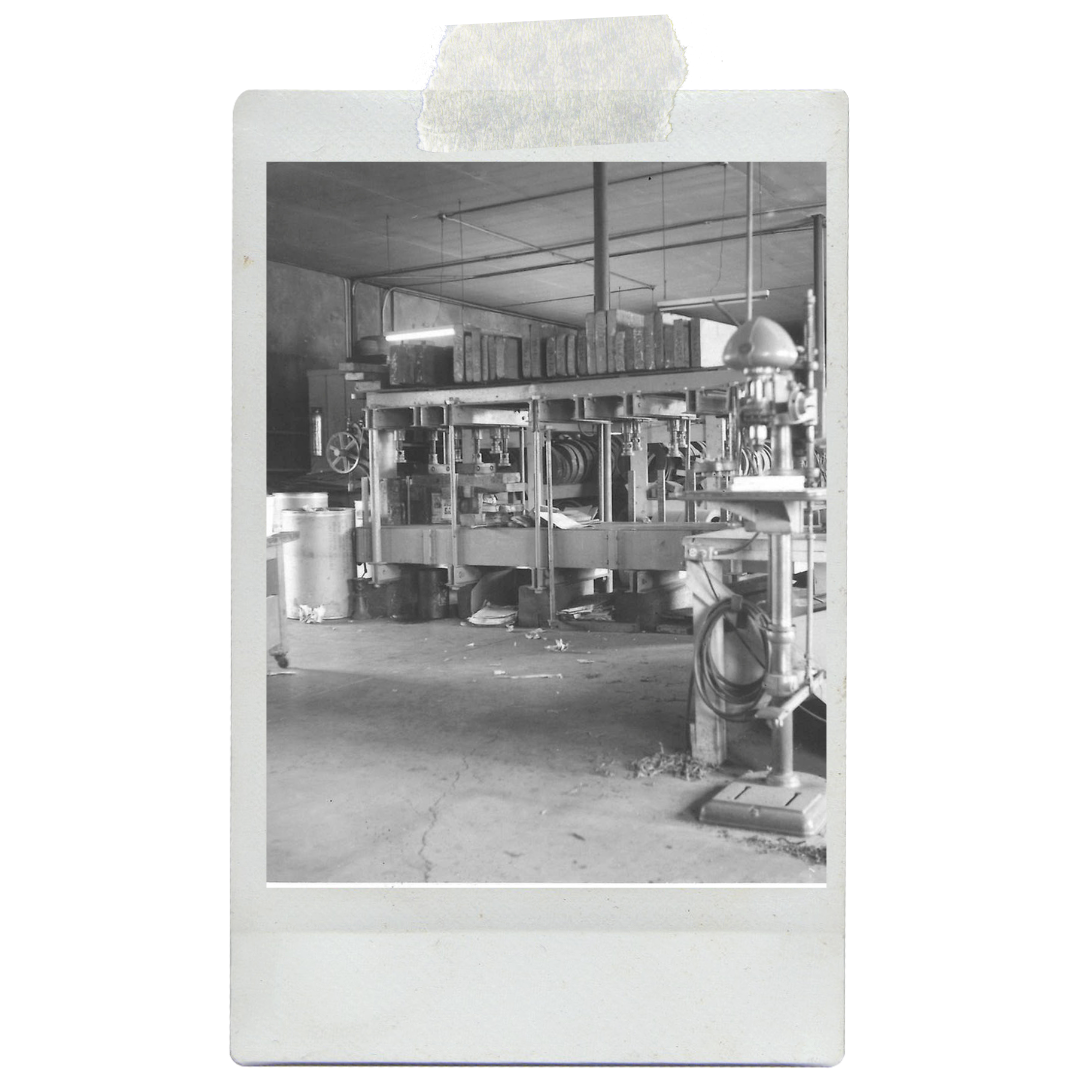

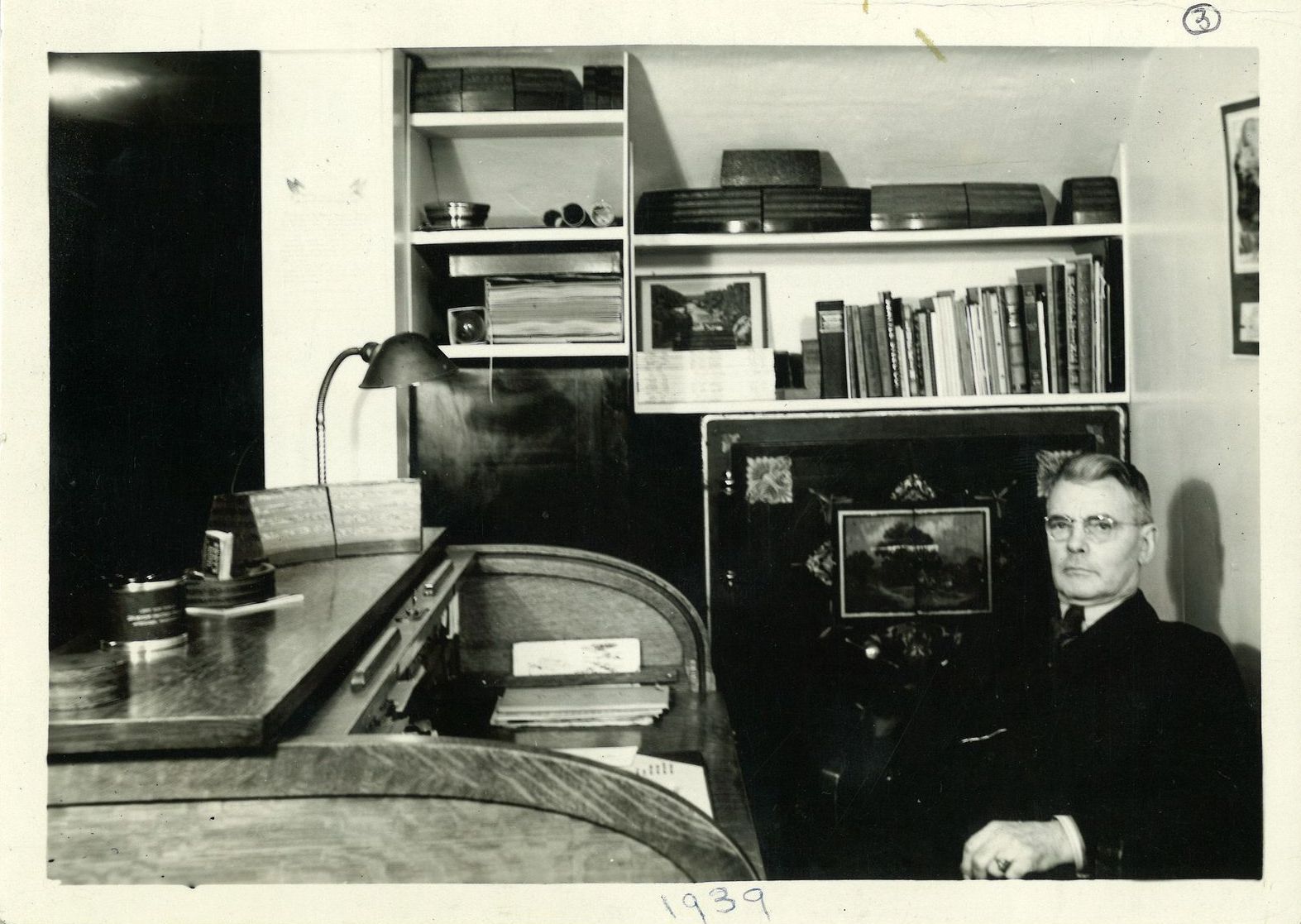

Champion Friction Technologies has always been a family business, but it’s also a story of American ingenuity at its best. Founded in 1927 by William H. Clubb in Aberdeen, Washington, Champion began by supporting the logging industry’s steam donkeys—those iconic machines that powered the timber boom. The very first friction blocks William made are still produced today, a testament to the durability and quality that built our reputation. In those early days, William pressed friction material together by literally jacking up his family home, strapping the furniture to the walls, and using the weight of the house as a makeshift press. As the business grew, he moved into a downtown Aberdeen shop—though not without some colorful distractions upstairs, courtesy of the neighborhood “cat house.”

Founded - 1927

William H. Clubb founded Champion in Aberdeen, Washington - 1927

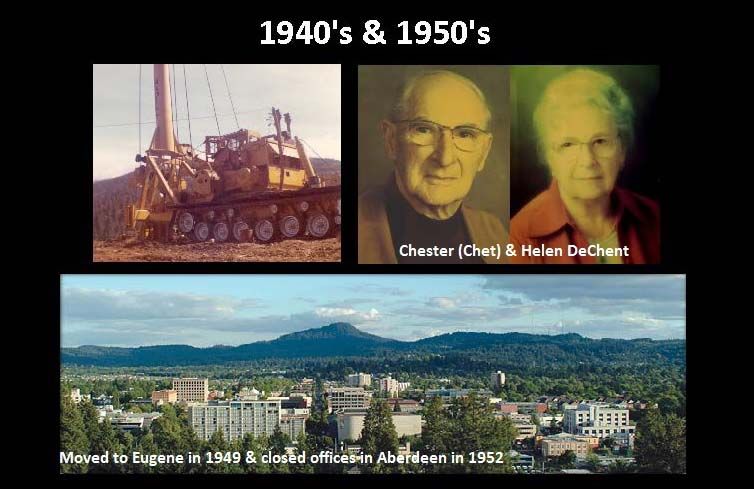

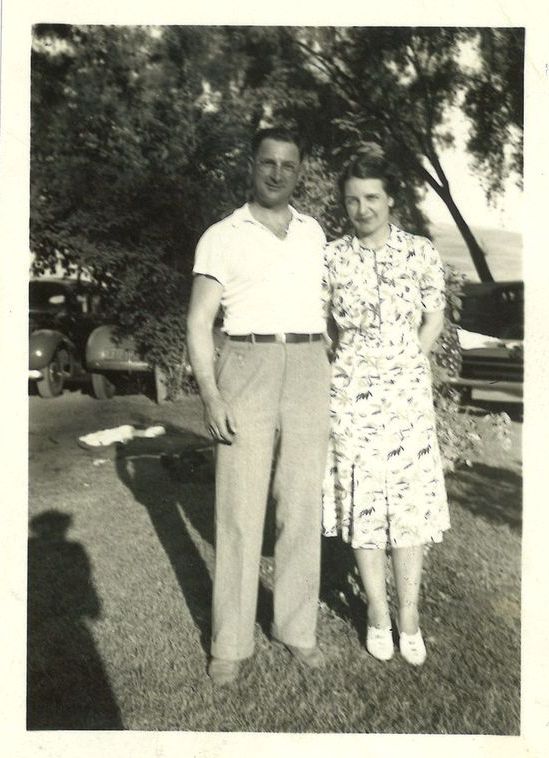

Helen & husband Chet took over the business and moved it to Eugene, Oregon in the 1940s.

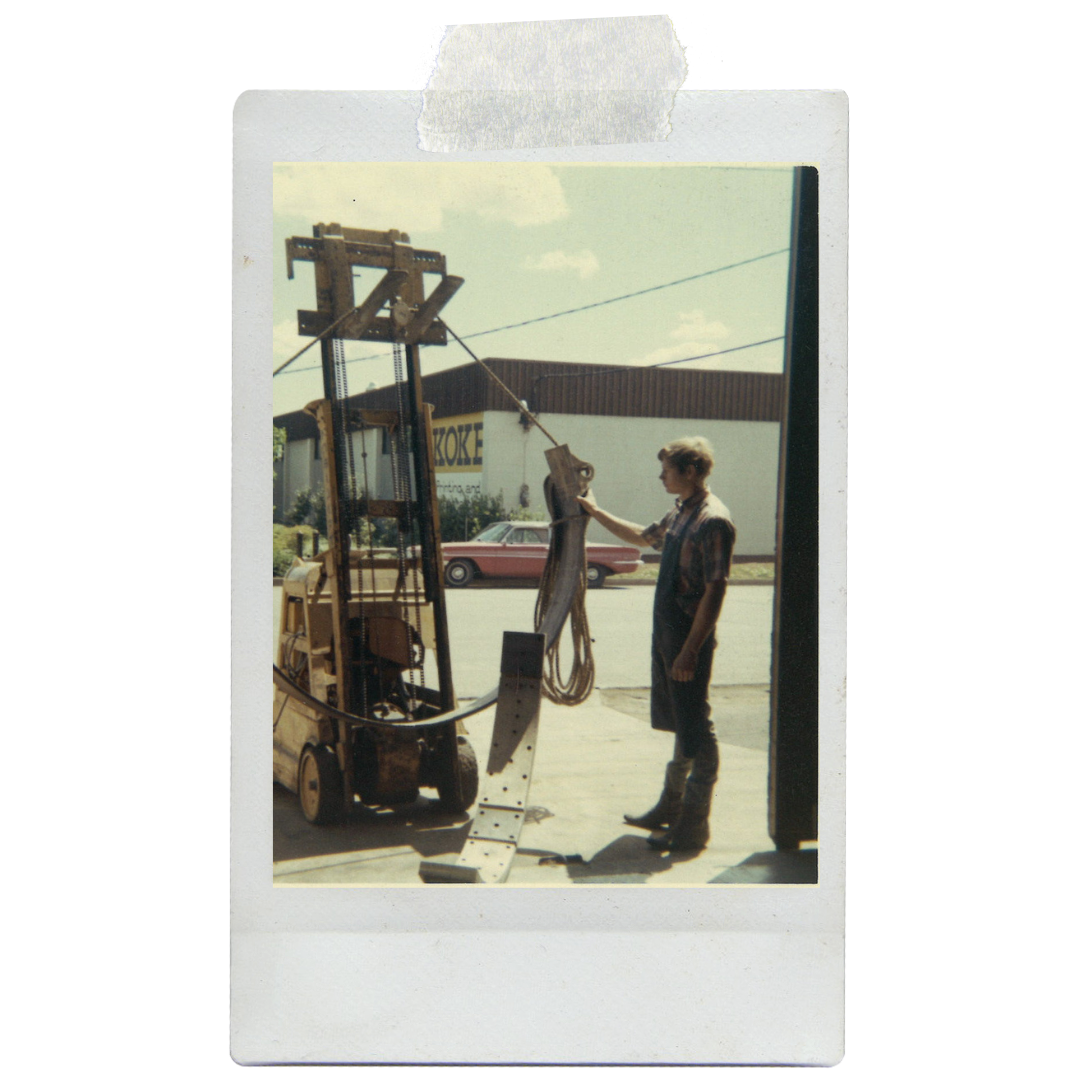

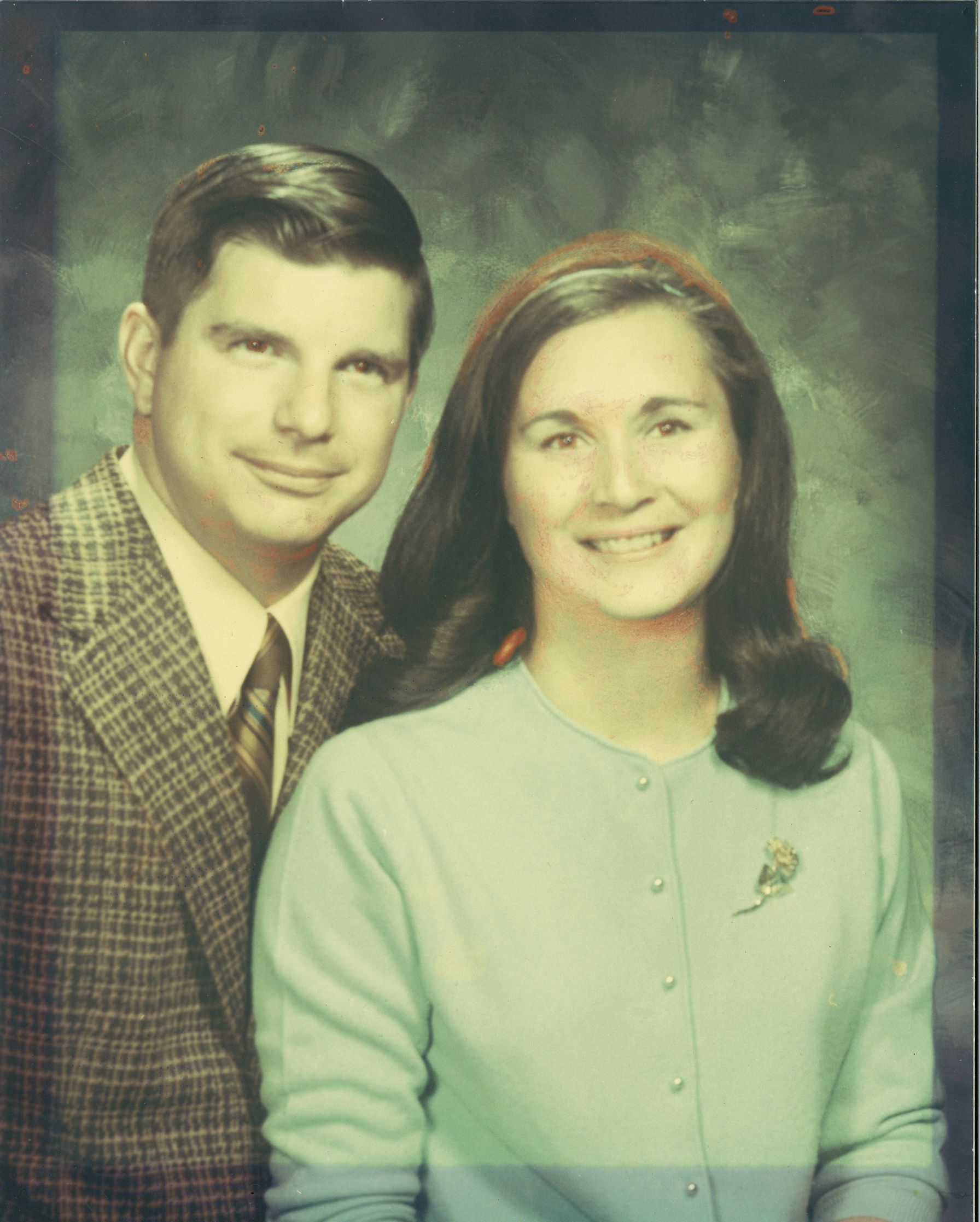

Champion’s legacy was carried forward by William’s daughter, Helen, and her husband Chet, who helped move the business to Eugene, Oregon in the late 1940s. Together, they built a company that became essential to the logging industry in Lane County. By the 1970s, Champion was expanding, developing steel brake bands and pioneering products like EZGlide, an “anti-friction” solution for sawmills. William “Bill” DeChent, Helen’s son, joined full-time in the 1960s, growing the company into new markets and helping Champion develop custom solutions for the U.S. military, marine, rail, and construction industries as the Northwest logging trade began to change.

William “Bill” DeChent joined the company in the 1960s

William "Bill" DeChent and wife Gayle

The 1980s and 1990s saw the birth of Advanced Friction Technology (AFT), Champion’s own line of friction compounds. When Bill’s daughter Robyn joined the company in 1996, she brought new energy and vision. In 2005, Champion Friction Co. and AFT merged to become Champion Technologies Inc., combining nearly a century of expertise under one roof. Today, Robyn leads the company, and the fifth generation—her children Natalie and Alex—have joined, bringing new skills in welding, business management, and a deep understanding of what makes Champion unique. As we approach our 100th anniversary in 2027, we’re proud to be the trusted source for industrial brake and friction products across industries as diverse as logging, mining, marine, government, construction, rail, and even ziplines and dental chairs. Champion Friction Technologies stands for quality, history, and family—we look forward to serving you for the next hundred years.

The Legacy Continued

From left to right: Alex (son), Robyn, & Natalie (daughter)