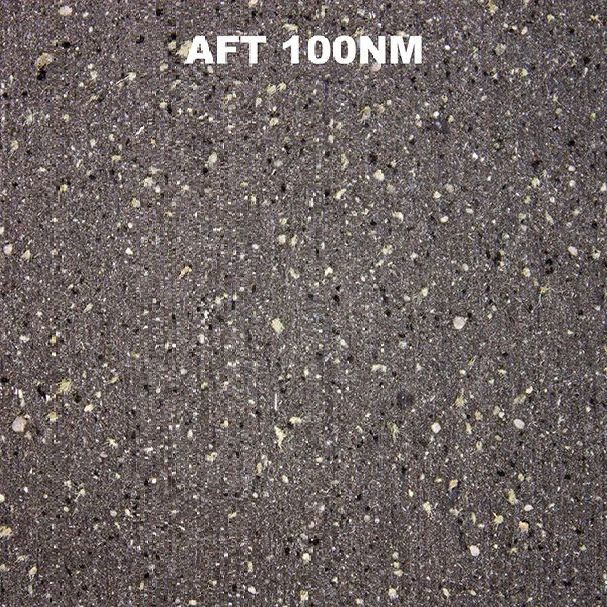

AFT100NM

Experience superior braking performance with AFT100NM, our advanced non-metallic friction composite engineered for demanding industrial and off-road applications. This premium material combines a medium-high coefficient of friction with exceptional durability, delivering consistent performance when you need it most.

This versatile friction composite excels in challenging environments, offering outstanding fade resistance and minimal wear rates. Available in both flat slabs and precision-molded parts, AFT100NM maintains its reliable performance characteristics throughout its service life.

Product Features:

Available Standard Sizes:

- Sheet Stock: Available in many sizes

- Sheet Size - 27" x 38"

- Thickness- .100" to 3"

Properties:

- Coefficient of Friction - .48 typ - GF

- Tensile Strength - 3150 psi

- Flexual Strength - 5625 psi

- Compression Strength - 17,750 psi

- Direct Shear Strength - 5220 psi

Current Applications:

- Hydroelectric Generator Blocks

- Agricultural Equipment Clutch Discs

- Tear Drop Blocks

- Paper Winder Pads

- Industrial Brake Linings

- Disc Brake Pads

- Aircraft

Suggested Operating Limits:

- Max Pressure - 250 psi

- Max Surface Speed - 5000 ft/min

- Max Intermittent Temp - 650°F

- Max Sustained Temp - 550°F

Specialized for Hydro-Electric Applications

AFT 100 NM's non-metallic composition makes it the preferred choice for hydro-electric installations where metallic content must be minimized. Its unique formulation ensures consistent performance while meeting strict material requirements for these specialized applications.

Easy Integration

Compatible with standard machining processes and industry-accepted practices, AFT 100 NM integrates seamlessly into your manufacturing workflow. This material can be easily customized to your specific dimensional requirements without specialized tooling or techniques.

Why Champion?

Advanced Manufacturing Capabilities:

Our specialized equipment can produce specialized molds and laminated semi-cured slabs, enabling the creation of thicker, more precise drum parts that meet your exact requirements.

Custom Solutions:

Need a specific configuration? Our experienced staff works directly with you to develop friction solutions tailored to your application needs.

Contact our technical sales team to discuss your specific requirements:

Email: Sales@stillchampion.com

Toll-Free: (800) 547-6180

Trust Champion Friction Technologies for industry-leading friction materials that deliver reliable performance when it matters most.