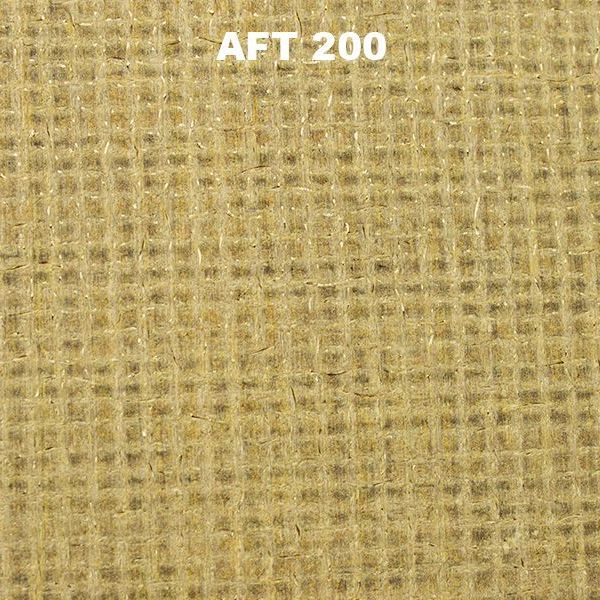

AFT200

Experience superior performance with AFT200, our premium phenolic-treated friction material engineered for demanding industrial applications. This advanced composite combines brass wire-inserted cloth, precisely laminated under controlled heat and pressure to create an exceptionally durable and reliable friction solution.

Ideal for heavy-duty applications, AFT200 excels in gear-driven systems and lug-drive mechanisms where reliability is crucial. Every AFT200 component is manufactured to exact specifications, ensuring consistent quality and dependable operation in your most challenging friction applications.

Product Features:

Available Standard Sizes:

- Sheet Stock is available in many sizes

- Thickness- .125" to 3"

Properties:

- Coefficient of Friction: .42 typical @400 F

- Tensile Strength, psi: 7200

- Flexural Strength psi: 20,500

- Compression Strength psi: 30,000+

- Shear Strength, psi 13,600

Current Applications:

- Brake or Clutch Pads

- Industrial Brake Linings

- Geartooth Facings

- Robotics/Electric Motors

- PTO's

- Small Winches

- Agriculture applications

Suggested Operating Limits

- Maximum pressure, psi 250

- Maximum Surface Speed, ft./min 5000

- Maximum Intermittent: 600 deg.

- Maximum Sustained: 500 deg.

Why Champion?

Advanced Manufacturing Capabilities:

Our specialized equipment can produce specialized molds and laminated semi-cured slabs, enabling the creation of thicker, more precise drum parts that meet your exact requirements.

Custom Solutions:

Need a specific configuration? Our experienced staff works directly with you to develop friction solutions tailored to your application needs.

Contact our technical sales team to discuss your specific requirements:

Email: Sales@stillchampion.com

Toll-Free: (800) 547-6180

Trust Champion Friction Technologies for industry-leading friction materials that deliver reliable performance when it matters most.